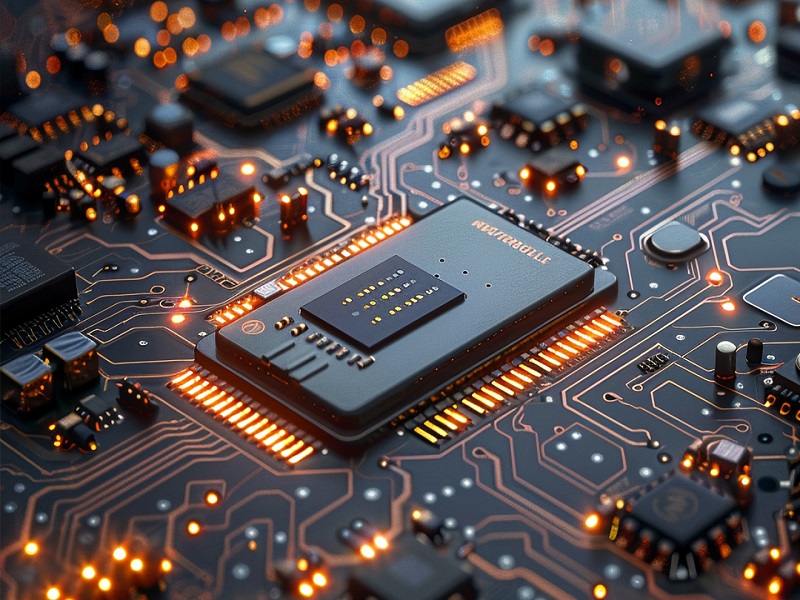

In today’s technology-driven world, printed circuit boards (PCBs) are the backbone of modern electronic devices, ranging from simple consumer electronics to sophisticated telecommunications and robotics systems. Global Well PCBA, a prominent Chinese PCB and PCBA manufacturer, has become a key player in this rapidly growing industry. Known for their technical expertise, innovative PCB solutions, and commitment to quality, Global Well PCBA serves a diverse range of industries by offering cutting-edge PCB fabrication and assembly services.

This article explores the advanced capabilities of Global Well PCBA, with a focus on their expertise in producing Rigid-Flex and High-Frequency PCBs, and how their solutions contribute to various industries, including telecommunications and robotics.

The Role of PCB Manufacturing in Modern Electronics

Printed circuit boards (PCBs) are essential in powering a vast range of electronic devices by providing mechanical support and connecting electronic components like resistors, capacitors, and integrated circuits. As industries push the boundaries of technology, the demand for high-performance, reliable PCBs has skyrocketed. Global Well PCBA specializes in addressing these needs with precision and innovation, ensuring that their clients have access to the most advanced PCB solutions available.

Technical Expertise at Global Well PCBA

Global Well PCBA’s strength lies in its deep technical expertise and ability to produce custom, complex PCBs tailored to meet the unique needs of each client. The company offers an array of services that include printed circuit board design, prototyping, and full-scale production. Their manufacturing facilities are equipped with state-of-the-art technology that ensures precision and quality in every PCB produced.

Advanced Design and Prototyping

One of Global Well PCBA’s key offerings is advanced PCB design and prototyping services. Their team of engineers and technicians works closely with clients to create PCB layouts that meet specific design requirements, ensuring optimal performance and functionality. By leveraging sophisticated software and design tools, Global Well PCBA ensures that their prototypes are accurate, reliable, and ready for mass production.

The ability to quickly create and test prototypes allows their clients to reduce development time and costs, while ensuring that the final product meets all necessary performance standards. This process is particularly crucial in industries like telecommunications and robotics, where innovation and time-to-market are critical factors.

Rigid-Flex PCBs: A Key Solution for Compact, Complex Devices

Rigid-Flex PCBs are one of Global Well PCBA’s standout offerings. These advanced boards combine the durability of rigid PCBs with the flexibility of flexible circuits, making them ideal for use in compact, complex devices that require a high degree of functionality within a small form factor.

What are Rigid-Flex PCBs?

Rigid-Flex PCBs are hybrid boards that consist of both rigid and flexible sections. This unique structure allows for more versatile design options, as the flexible areas can bend and twist, enabling the PCB to fit into tight spaces within a device. At the same time, the rigid sections provide structural integrity and support for mounting electronic components.

Rigid-Flex PCBs are commonly used in industries where compactness, reliability, and durability are essential. These industries include aerospace, medical devices, consumer electronics, and automotive applications, where devices need to withstand extreme conditions while maintaining high performance.

Global Well PCBA’s Expertise in Rigid-Flex PCBs

Global Well PCBA has established itself as a leader in Rigid-Flex PCB manufacturing. Their advanced production techniques and cutting-edge equipment allow them to create Rigid-Flex PCBs with multiple layers, enabling greater complexity and functionality in a smaller footprint. Their expertise in this area ensures that their clients receive PCBs that meet the highest standards of quality and reliability.

The company’s ability to produce high-quality Rigid-Flex PCBs is particularly beneficial for the robotics and telecommunications sectors. In robotics, where space and weight constraints are critical, Rigid-Flex PCBs allow for the development of smaller, more efficient robotic systems. In telecommunications, these PCBs enable the creation of compact devices that can handle complex signal processing and data transmission tasks.

High-Frequency PCBs: Powering Advanced Telecommunications and Robotics

As technology continues to evolve, the demand for high-speed, high-frequency PCBs has increased significantly. Global Well PCBA is at the forefront of this trend, offering High-Frequency PCBs that are specifically designed to handle high-speed data transmission and signal integrity in advanced electronic systems.

What are High-Frequency PCBs?

High-Frequency PCBs are designed to operate at frequencies above 1 GHz, making them ideal for applications that require fast data transmission and precise signal processing. These PCBs are commonly used in telecommunications, where they enable high-speed communication networks, and in robotics, where they support the processing of complex algorithms and real-time data.

Global Well PCBA’s Expertise in High-Frequency PCBs

Global Well PCBA’s High-Frequency PCBs are manufactured using advanced materials that ensure excellent signal integrity, minimal signal loss, and high-speed performance. The company’s expertise in producing these PCBs ensures that their clients have access to solutions that meet the stringent requirements of industries such as telecommunications and robotics.

In the telecommunications industry, high-frequency PCBs are essential for the development of 5G networks and other advanced communication technologies. These PCBs are designed to handle the high-speed data transfer and low-latency requirements of modern communication systems, ensuring that devices can operate efficiently even in high-frequency environments.

In the robotics sector, high-frequency PCBs enable the development of autonomous systems and advanced AI-driven robots. These systems rely on fast, accurate data processing to perform complex tasks, making high-frequency PCBs an essential component of modern robotics.

Quality Control and Reliability at Global Well PCBA

One of the hallmarks of Global Well PCBA’s success is their commitment to quality control and reliability. The company has implemented rigorous quality assurance processes to ensure that every PCB they produce meets the highest industry standards. Their manufacturing facilities are equipped with advanced testing and inspection equipment that allows them to detect and address any potential issues before products are shipped to clients.

Environmental Sustainability in PCB Manufacturing

Global Well PCBA is also committed to environmental sustainability in their manufacturing processes. They have adopted eco-friendly practices, such as using lead-free materials and reducing waste, to minimize the environmental impact of PCB production. This commitment to sustainability is an important aspect of the company’s overall approach to responsible manufacturing.

Applications of Global Well PCBA Solutions in Key Industries

Global Well PCBA’s advanced PCB solutions have found applications across a wide range of industries, including telecommunications, robotics, automotive, aerospace, and medical devices.

Telecommunications

In the telecommunications industry, Global Well PCBA’s high-frequency PCBs are essential for the development of 5G networks and other advanced communication technologies. Their Rigid-Flex PCBs also play a crucial role in enabling compact, high-performance devices that are used in wireless communication systems.

Robotics

In the robotics sector, Global Well PCBA’s expertise in Rigid-Flex and high-frequency PCBs supports the development of compact, efficient robotic systems. These PCBs are used in advanced robotics applications that require real-time data processing, high-speed communication, and precise control.

Automotive and Aerospace

Global Well PCBA’s PCBs are also used in the automotive and aerospace industries, where they provide reliable, high-performance solutions for applications such as advanced driver-assistance systems (ADAS), autonomous vehicles, and avionics.

Conclusion

Global Well PCBA stands out as a leader in the PCB manufacturing industry, offering advanced solutions like Rigid-Flex and High-Frequency PCBs that cater to the needs of a wide range of industries. Their technical expertise, commitment to quality, and focus on innovation have made them a trusted partner for companies in telecommunications, robotics, and beyond. As the demand for sophisticated electronic devices continues to grow, Global Well PCBA is well-positioned to remain at the forefront of PCB and PCBA manufacturing, delivering high-performance solutions that meet the evolving needs of the global market.